process & production

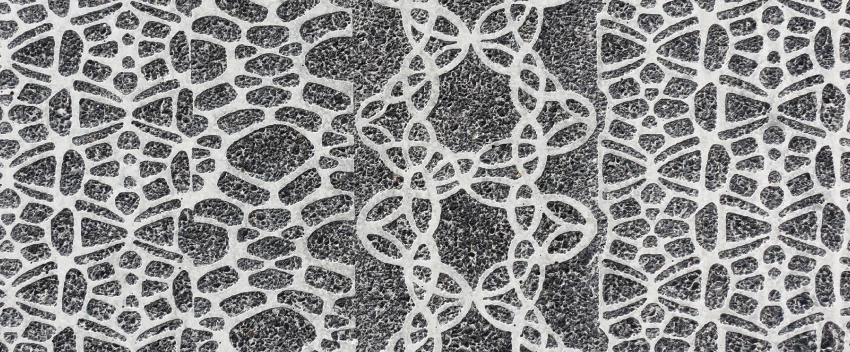

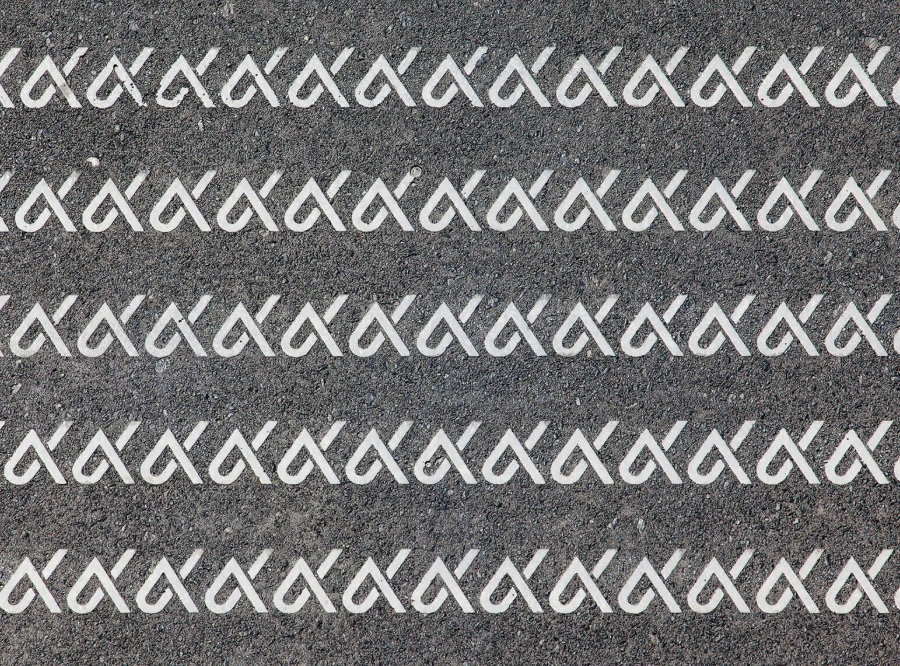

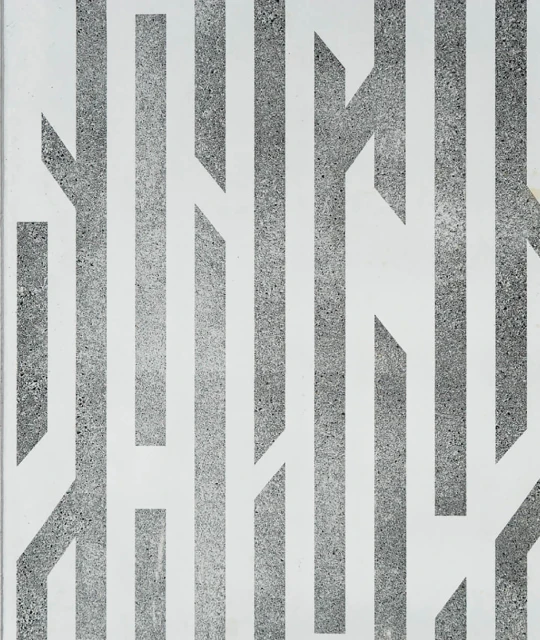

With its durable concrete and its ability to apply any pattern, image, or design to precast surfaces, Graphic Concrete offers countless creative possibilities.

During production, the technology transfers graphics onto concrete using paper that has been treated with a surface retarder. Smooth and exposed aggregate surfaces contrast sharply when the retarder is removed after it has cured. As a result, the finish is strong and requires little upkeep.

Using different pigments and aggregates to improve the finished look of precast concrete can make it look beautiful and new.

How to design your project

Graphic concrete is ideal for horizontally cast precast products like slabs, walls, and facades. It is compatible with all panel sizes and standard concrete mixtures. Contact us soon for ready-made patterns or custom designs to guarantee the most significant outcomes. We are here to support your success, having worked on over 1,000 global projects.

How to design your pattern

Any design you can draw can be applied to precast concrete to create a striking facade or surface. Designing a Graphic Concrete pattern is straightforward but requires understanding repetition, contrast, and raster use.

Consider viewing distances, colors, and contrasts to ensure the design is detailed up close and effective from a distance. Varying the colors of the cement and aggregate can greatly affect the final appearance.

For design tips and instructions, check below. Contacting us early in the project helps achieve the best and most cost-effective result.

How to design your concrete

Concrete and cement are not the same; cement is just one part of concrete. Concrete consists of water, aggregate (rock, sand, or gravel), and cement. The cement, usually a powder, binds with water and aggregates to form a durable material as it hardens.

How to produce Graphic Concrete

The Graphic Concrete manufacturing process is similar to creating a fine exposed aggregate surface using a liquid retarder. A special dry retarder paper is placed in the mold, and concrete is poured over it. The pattern emerges from the contrast between the exposed and smooth finishes. Various retarder strengths are available, selected based on the concrete mix and casting conditions through testing. GCTechnology training and materials are available upon request. For more details, please inquire.

discover more

View more

Product type

With our technology, any design concept can be brought to life on precast concrete surfaces. Whether you want a bold statement or a subtle backdrop, Graphic Concrete makes it possible. Your imagination is the only limit.

View more

pattern collection

Explore the GC Collection with 100+ patterns, or customize your own, without extra cost.