Flexbrick Concept

What Is Flexbrick Ceramic Tissue?

This presentation introduces an innovative concept: ceramic textile, an industrialized system of flexible baked clay sheets designed for tiling, cladding, and laminated structures with a ceramic finish.

These ceramic textiles unlock a wide range of possibilities for dry-assembly cladding systems in architecture. They can be used to “dress” facades, roofs, squares, and more, expanding the boundaries of textile architecture.

Projects utilizing this ceramic textile, such as drainable pavements, roof gardens, ceilings, and suspended light-permeable façades, showcase the extraordinary architectural potential of ceramic materials when applied within industrialized systems.

10 Advantages of Flexbrick Ceramic Architecture

- Sustainable: Flexbrick ceramic tissues are environmentally friendly as they are baked with biogas. The system’s dry-joined components make recycling it simple and enable easy separation and reuse.

- Large dimension formats: Flexbrick provides formats as large as 20 meters, which lowers labor costs and boosts productivity.

- Optimal execution performance: Crane laying simplifies installation and speeds up construction by integrating the finish in a single operation.

- Flexibility: Flexbrick sheets can be rolled into a coil or folded onto pallets for simple storage and transportation.

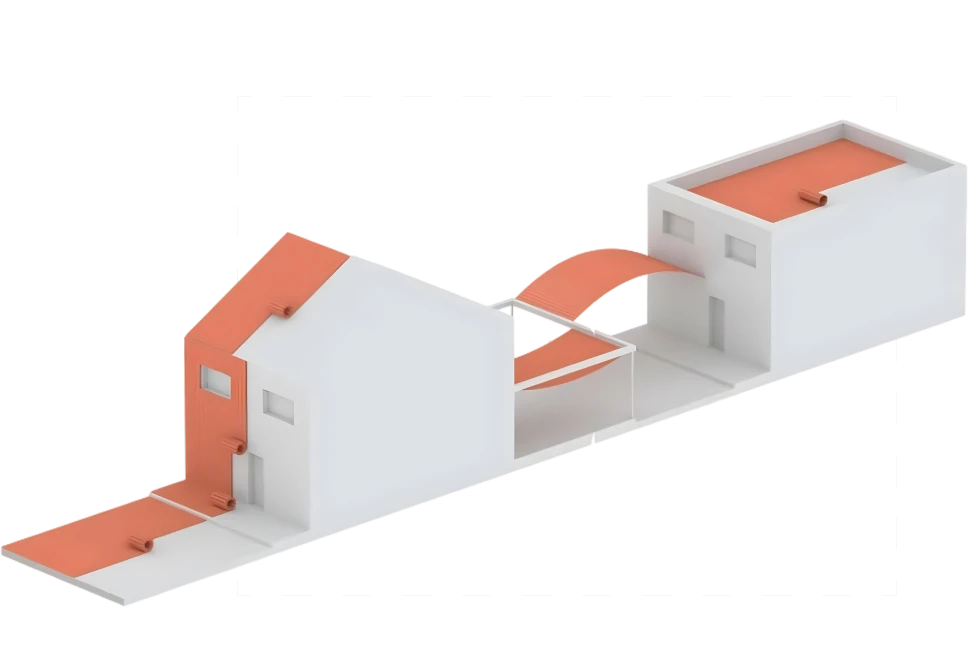

- Multipurpose: Flexbrick can be used seamlessly across pavements, facades, and roofing with only minor adjustments to the mesh components, allowing for continuous enclosure.

- Variability: A variety of tissue configurations and color choices are possible with this prefabricated system.

- Design: Flexbrick facilitates creative designs by combining different configurations, allowing for continuous enclosures, curved structures, and precise alignments, all while saving costs.

- Design: Flexbrick saves money by combining various configurations to enable continuous enclosures, curved structures, and exact alignments. This promotes creative design work.

- Expanded use of ceramic products: Flexbrick expands the traditional use of ceramics by opening up new markets in the fields of civil engineering and architecture.

- Easy maintenance: The roll and dry system makes maintenance easier by making collection for recycling or repairs simple.

From Past To Future

Flexbrick transforms ceramic surfaces with better installation methods, giving a contemporary take on an age-old material.

This creative system combines ceramic clay tiles arranged in bands both horizontally and vertically with interwoven steel wire mesh. It transforms conventional ceramics into a new, more effective format that makes the process of installing them piece by piece easier.

Flexbrick is incredibly flexible and can be folded up for easy storage and transportation, which saves room and facilitates movement. The lengthy strips make installation quick and affordable while also assisting in the reduction of emissions.

No Ordinary Profiles Are Required The Construction Time Is Reduced

Flexbrick’s speed in covering surfaces is its main advantage. Flexbrick presents tiles, bricks, and cobbles on large sheets that can cover walls and floors, rather than placing them one by one. It is quicker and simpler to handle because of its large format, especially on large surfaces where cranes can efficiently place the strips.

Flexbrick provides a cost-effective solution for façades by eliminating the requirement for conventional profiles and supports. Given their inherent weight, the strips align vertically, requiring less additional material and requiring less time to install.

A Large Format Of Small Elements Accuracy Large-Scale Formats

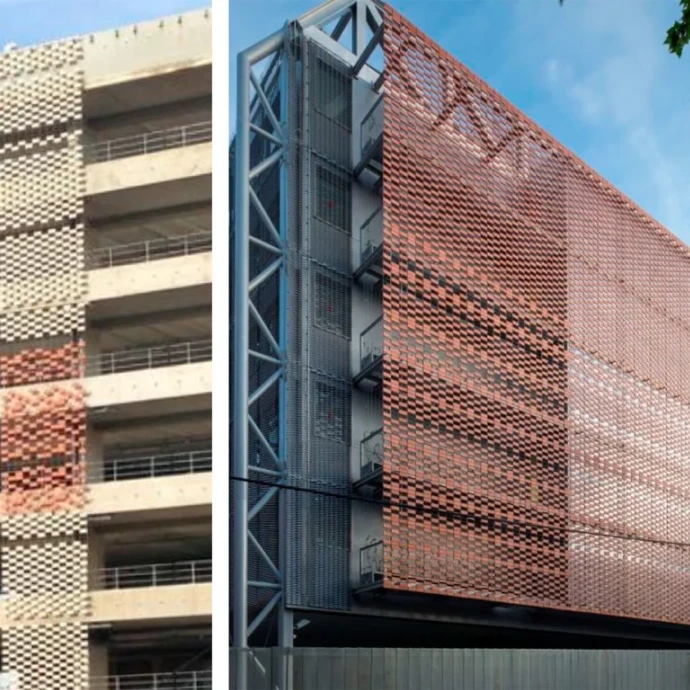

A Flexbrick ceramic fabric façade can be installed with the same ease as a curtain. The fabric is fastened to stainless steel rails, which are then bolted onto support brackets fastened to the building.

When building, Flexbrick saves time and effort with large-scale formats up to 20 meters. Given that the metal mesh keeps everything precisely in place, it works particularly well for sunscreens or suspended, light-permeable facades.

Light-Permeable Façades;

Ceramics Manufactured Using Biogas

A Sustainable System

This light-permeable lattice or façade reduces solar radiation and creates tempered spaces on buildings by acting as a natural sunscreen.

Flexbrick is made entirely of steel mesh and ceramic components, which are readily separated for recycling, making it easy to recycle.

Biogas from landfills is used to make ceramics at Flexbrick. With this approach, which is a unique process in Europe. Annual energy consumption is reduced by 5,000,000 Nm3, and annual carbon dioxide and greenhouse gas emissions are reduced by approximately 16,700 tonnes.